Wet algae is harvested and squeezed into a paste. It is now ready to be dried

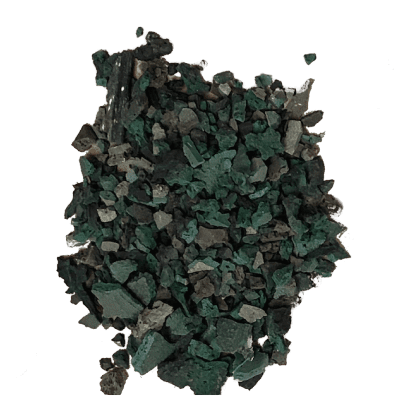

Using heat, the algae is paste is dried to create crunchy flakes.

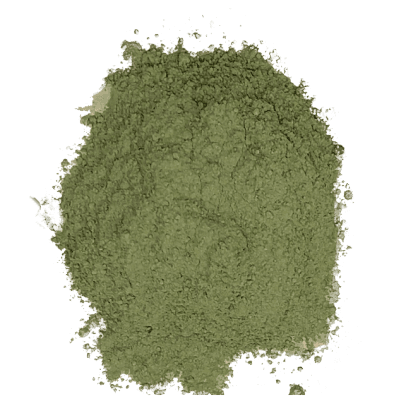

BLOOM’s proprietary processes are used to refine algae flakes into unique blends of green powder.

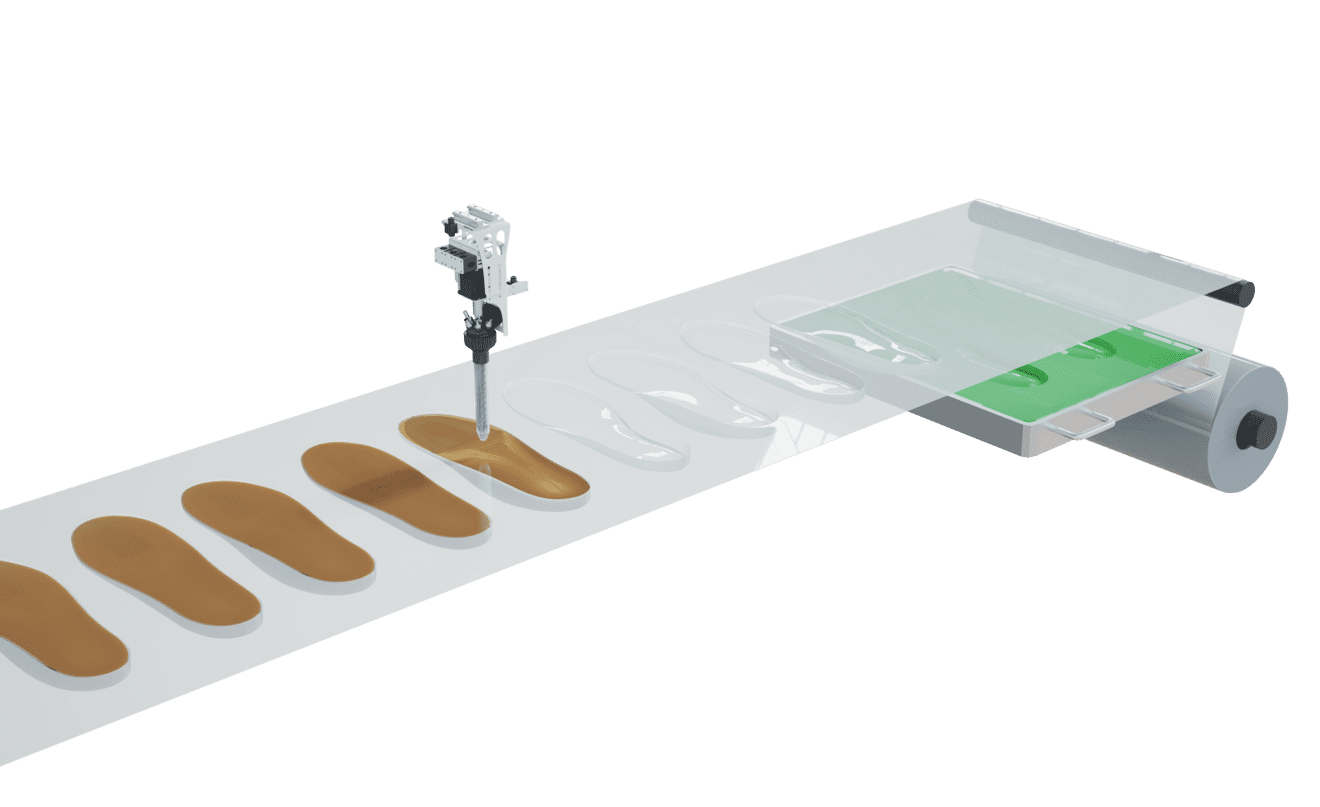

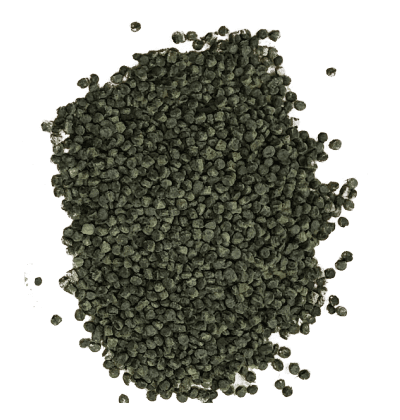

The algae powders are then blended with polymers to produce a variety of BLOOM® materials that are ready to be made into products!